CAST IRON

Cast irons are made of iron – carbon – silicon alloy. The common dispersion throughout the material is 2-4% carbon 0,4-3% silicon, 0,4 – 0,8% manganese, 0,1 – 0,8% phosphor and 0,05 – 0,10% sulfur. Cast irons are classified as follows according to the shape of their carbon content:

1. LAMELLA GRAPHITE CAST IRON

Lamella graphite cast iron is a cast iron that contains lamellar shaped graphite in composition.

2. SPHEROIDAL GRAPHITE CAST IRON

2. SPHEROIDAL GRAPHITE CAST IRON

Spheroidal graphite cast iron is a cast iron that contains spheroid shaped graphite in composition. It is also referred to as SPHEROIDAL CAST IRON. In order to ensure the conversion of the carbon shape from lamellar to spheroid, a small amount of magnesium (mg) or cerium (ce) is added to the molten cast iron. Due to the graphite structure, the cast iron obtained by a specific method is also referred to as spheroidal graphite cast iron. Spheroidal graphite provides softness (flexibility) to cast iron. The split surface has a shiny appearance.

2.1. ABOUT SPHEROIDAL GRAPHITE CAST IRON

The chemical composition of Spheroidal Graphite Cast Iron is usually available among the following limits:

| % COMPOSITION | ||

| Carbon | (C) | 3.00-4.00 |

| Silicon | (Si) | 2.00-3.00 |

| Manganese | (Mn) | 0.10-0.90 |

| Phosphor | (P) | 0.10 Max. |

| Sulfur | (S) | 0.03 Max. |

| Magnesium | (Mg) | 0.030-0.080 |

| MICRO-STRUCTURE AND CHEMICAL CHARACTERISTIC OF SPHEROIDAL GRAPHITE CAST IRONS | |||||

| Material Type | GGG 40 | GGG 50 | GGG 60 | GGG 70 | GGG 80 |

| Micro-structure | FERRITIC | |

PEARLITIC | ||

In addition to the spheroding elements and sulfur, the effects of carbon (c), silicon (si), manganese (mn) and phosphor (p) in the composition on the features of alloy are similar to that on the cast iron characteristics. While the carbon (c) amount in the composition increases, the alloy resistance decreases. As in the grey cast iron, phosphor is an element which provides fragility also in spheroidal graphite cast iron. Therefore, the phosphor (p) amount in the alloy must be kept at minimum as approx. 0,10%. The approximate manganese (mn) content of the alloy must be max. 0,50% in order to avoid the alloy’s stiffness and fragility. Sulfur (s) is the element with the highest restriction of use for the spheroidal graphite cast iron to prevent the decrease of the influence of spheroiding elements which should not exceed 0.02% in the composition.

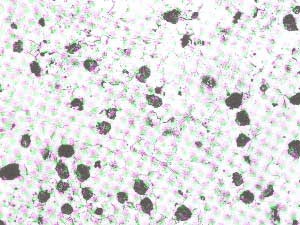

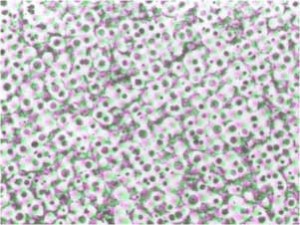

2.1.b THE MICRO-STRUCTURE OF SPHEROIDAL GRAPHITE CAST IRON

The spheroidal graphite cast iron that features an austenite structure in high temperatures has a different structure in temperatures below 735°C. The amount of carbon (c) soluble in austenite is around 1%. Carbon (c) solves very few in Ferrite. Therefore, 1% carbon is separated from austenite during the austenite-to-Ferrite conversion. The separated carbon becomes carbide and stiffens on the present spheroidal graphites.

In case of enough to time for spheroid graphite conversion, the complete carbon solved in austenite consists of randomly dispersed spheroid graphites within the ferritic structure. In many cases, it cannot proceed to the areas where the carbon graphites separated from austenite are available and cannot find time to stiffen. In this case, graphites emerge in the form of thin carbide layers. Such carbide layers spoil the stability of the ferrite structure. Ferrite and carbide layers emerge adjacent to each other while such structure is referred to as pearlite.

After this introduction, it is possible to view one or more of the structural components within the spheroidal graphite cast iron structure. The chemical composition as well as the field of use has an important role in the formation of these structures.

2.1.c FERRITIC SPHEROIDAL GRAPHITE CAST IRON

There are 3 methods of production of ferritic structure cast iron:

Addition of magnesium alloy to fluid cast iron in amounts suitable to its weight,

Heat processing of pearlitic graphite cast iron,

Extreme slowdown of the stiffening process of fluid spheroidal cast iron.

Ferritic spheroidal graphite cast iron has an extremely high elongation percentage.

2.1.d PEARLITIC SPHEROIDAL GRAPHITE CAST IRON

2.1.d PEARLITIC SPHEROIDAL GRAPHITE CAST IRON

It is a structure available in cast components with a section thickness up to 50mm. Offers hard alloy and good mechanical features.

2.1.e AUSTENITIC SPHEROIDAL GRAPHITE CAST IRON

2.1.e AUSTENITIC SPHEROIDAL GRAPHITE CAST IRON

It is a corrosion proof alloy with high mechanical characteristics. The structure is made of austenite and very few amount of pearlite.